5 Reasons for an Investor to Go Thermophilic for Digestion of Rice Straw in India

Investors are cautious people and want to avoid risks. Mesophilic is common and known. The

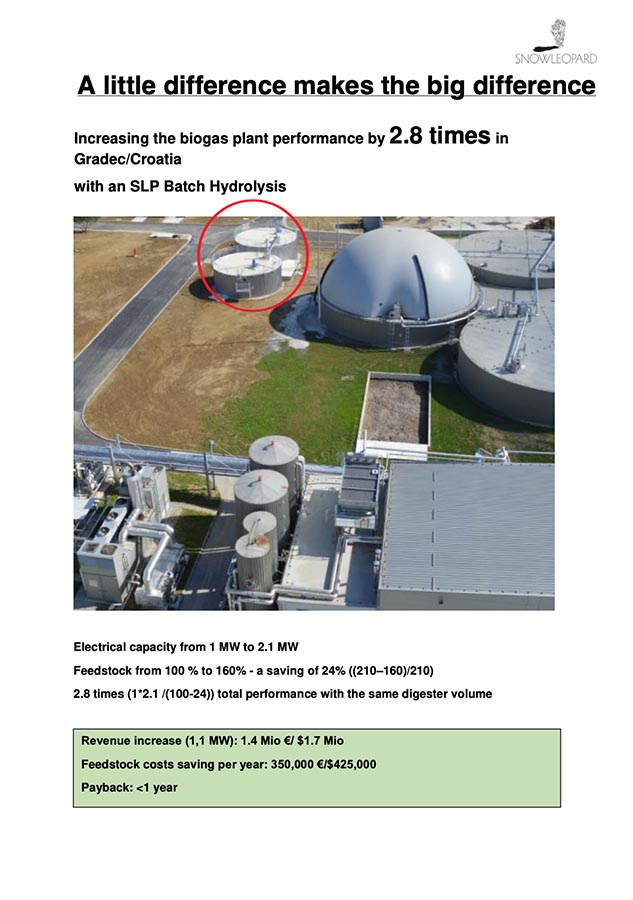

In Gradec, Croatia, we have increased the performance by 2.8 times. You can find more details in the PDF file (Free Download)

If you want to have a biogas plant, which

then the SLP High Performance AD plant is perfect for you.

We achieve these results by mocking the cow digestion. The paunch of a cow is our Batch Hydrolysis Tank. In this tank we break down the hardest fibre and can cope the highest organic loads from slaughterhouse waste.

With this front-end Batch Hydrolysis Tank we created a 2-stage digestion system (cow digestion) , while most of the biogas plants run on single stage (pig digestion)

We design and build biogas plants since 1995.

SLP built more than 50 plants in 14 countries on 4 continents.

The capacity range is from 10 kW to 4 MW.

SLP 2-Stage Biogas Plants with Batch Hydrolysis are ideal for

Investors are cautious people and want to avoid risks. Mesophilic is common and known. The

UNIDO (United Nation Industrial Development Organization) has accompanied and support numerous biogas, biomass and biofuel projects in the past worldwide. To compile and share experience, UNIDO held an Expert Group Meeting on biomass with participants from various countries and backgrounds to discuss the lessons learnt for successful biomass projects.

Katharina Danner was invited as resource person for biogas, giving her expertise on international biogas projects to the participants.

Benefit 1: Up to 50 % less nutrients at the same biogas quantitiy makes it easier to match with the fertiliser ordinance.

Benefit 2: No new final storage necessary because straw contains only little water. Separation even pulls water out of the system.

Benefit 3: Straw has a calculable price because no animal wants to have it will.

© Snow Leopard Projects • 2023 • all rights reserved