Investors are cautious people and want to avoid risks. Mesophilic is common and known. The biogas yields are poor. Operating thermophilic saves Capex and Opex and boosts ROI

My Indian partners were very hesitant to accept my proposal to operate rice straw biogas plants thermophilic (55+ °C). The biogas mainstream in India goes mesophilic (37-44 °C). Actually, almost everywhere around the globe plants go mesophilic when it comes to biogas. But why?

A biogas plant is considered to be a technical cow. A cow is a mammal with 37 °C body temperature. Even the German laboratory standard temperature for biogas yield test is 37°C. Therefore, when the biogas business started, people started to operate biogas plants mesophilic.

Times are changing. People learn. More knowledge and experience were gained. Biogas plants started to raise temperature.

When I increased the temperature to 44 °C in my own biogas plant back in 2003, I thought this is the ceiling. I was wrong.

My friend, I built his biogas plant in 2005, increased to 55 °C. Results were better yield, less feedstock needed, lower viscosity, lower parasitic load, lower OPEX, higher profit.

I followed. Other followed to thermophilic. The same success.

2014 – my friend increased the temperature to 62 °C in the hydrolysis tank and kept the temperature in the digester at 55 °C. Even better results.

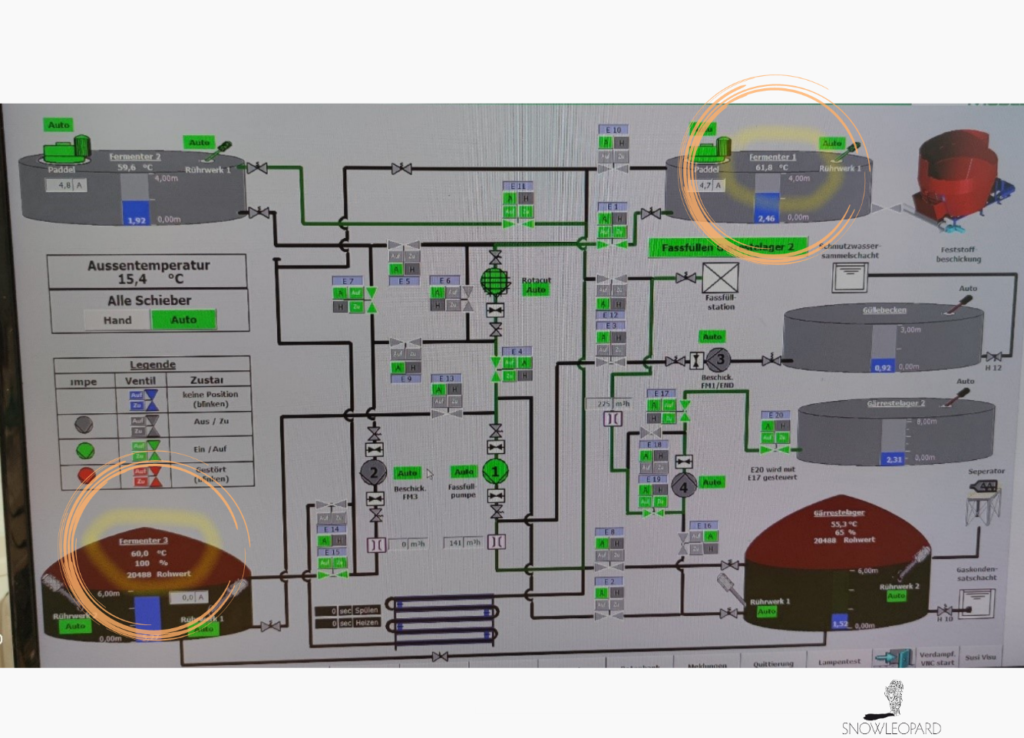

2022 – another friend, whose biogas plant I built, operates his hydrolysis at 61-62 °C and his digester at 60 °C. (see photo)

Hyper-Thermophilic!!!

The results are exceptional. Biogas yield is 35% above the regular biogas yield. There´s only a very low parasitic load because the mixers run only 4 minutes every half an hour, though fibrous material like straw-based manure and others are a big part of the feedstock mix. The solid-liquid screw separator can’t separate any solids because the dry matter is fully digested.

“Maintaining the temperature is difficult.” – In Germany we maintain this temperature even in winter with -20 °C. We insulate the tanks. Maintaining the temperature is much easier in India due to higher ambient temperatures. A proper tank insulation is the key to low heat losses.

“Higher capex with thermophilic installation.” – (Wrong) The capex is lower, because with the higher temperatures the retention time is shorter. So, less digester capacity is needed, shorter pipes, smaller footprint. The slightly higher costs for heating coils and insulation is easily compensated by savings in civil works and piping.

“Using gas for heating purpose” – yes, a bit more gas or heat from the CHP is required to achieve thermophilic temperatures. With 35% more biogas from the same feedstock, you can sacrifice 1% for heating. It still is a huge surplus in energy yield!

“No successful thermophilic biogas plant in India” – No one wants to be the first. No one wants to take the risk. 100 years ago, entrepreneurs, who wanted to stick to horses for transport instead of using a lorry, went bankrupt. Henry Ford became a billionaire.

Why thermophilic beats mesophilic with rice straw!

All the practical experience and observations are backed by science and make sense when you look at the biological processes taking place.

Higher temperatures accelerate the enzyme activity in the biogas plant.

More biogas in shorter time is produced.

This reduces the retention time, the required digester volume and the capex!

Lower viscosity reduces the electricity consumption of mixers and pumps. This is a huge saving in OPEX.

And lower viscosity leads to less wearing of the equipment and therefor lower maintenance cost.

More biogas from the same amount of feedstock.

This reduces the amount of feedstock. Feedstock is the main part of the OPEX. Less costs leads to higher profit.

Lower risk with future price increase for feedstock.

There are additionally many smaller advantages and details, which would fill several pages.

The Killer-Evidence for thermophilic

Most of the German biogas plants were built cheaply for the digestion of maize silage. Maize silage is the main fodder crop in Germany. Easiest to digest.

Prices for maize silage went up and fibrous feedstock is cheaper. But the biogas plants can’t cope with fibre.

With higher ambient temperatures in summer the biogas plants can operate thermophilic. Best results.

Late autumn, winter and early spring the cold ambient temperatures lead to lower temperatures (mesophilic) in the biogas plants, because they are equipped with cheap heating systems.

Performance goes down!

Late spring with higher ambient temperatures and back to thermophilic performance recovers.

More evidence for thermophilic is not possible!

Germany goes thermophilic

The German biogas plants started mesophilic. But one by one goes thermophilic. Especially, because they replace the now very expensive maize silage with cheap straw-based manure, grass and straw.

If you are interested in this topic, but not fully convinced send me an email (w.danner@snow-leopard-projects.com)